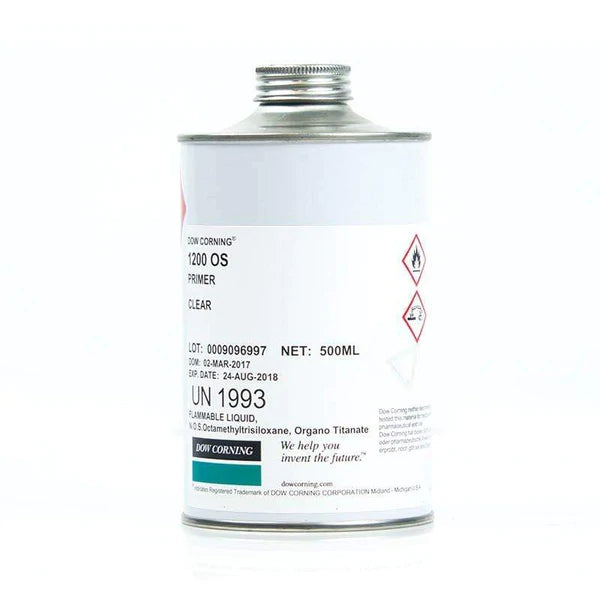

DOWSIL™ 1200 OS Primer

Primer for silicone adhesives and sealants

An air-drying primer supplied as a dilute solution of moisture-reactive materials in volatile siloxane and is used to improve both the quality and rate of room temperature adhesion of vulcanizing silicone sealants to a variety of commonly used non-porous substrates.

Application Applications

- Battery pack, plates and assemblies, components, connectors, engine systems, housings

- DOWSIL™ 1200 OS Primer improves the bond/adhesion of RTV and thermosetting silicones to many materials:

- Metals

- Ceramics

- Glass

- Wood

- Masonry

- Engineering plastics

Features and Benefits

- Improves the adhesion of silicone sealants to many substrates

- Useful for both moisture-curing RTV silicones and thermosetting silicones

- Provides more uniform and stronger bonds

- Complies with South Coast and Bay Area Air Quality Management Regulations for architectural waterproofing subfloors

- Low VOC (Volatile Organic Compounds) level of 76 g/l Meets many international regulations including the European Union

- Formulated for low toxicity

- The OS solvent used does not deplete the ozone layer. Labeling = ozone safe

- The primer is suitable for weather sealing and structural glazing applications

- Suitable for most metals, glass, ceramics, masonry, wood, fabrics and some plastics (including FR-4)

properties

| Adhesion to | Marble, Metal, Ceramics, Wood, Plastics |

| Color | Transparent, red |

| Flash point, closed cup | 27 °C |

| Shelf life | 540 days |

| Volatile organic content | 76g/litre |

| Specific gravity at 23°C (73.4°F) | 0.84 |

| Viscosity at 23°C (73.4°F) mPa.s | 1 |

Usage

For many surfaces, much stronger and more uniform bonds are achieved by pre-priming them prior to applying the silicone sealant. For best results, follow the steps below on all surfaces except silicone rubber.

- If necessary, thoroughly clean and degrease the surface with 2 cloths and a suitable solvent. Leave the surface to dry.

- Apply a thin layer of DOWSIL 1200 OS Primer with a clean white cloth or brush. In most cases, a thin layer of primer will provide the best adhesion. If you notice a white chalky residue after a few minutes of drying, wipe it off with a clean cloth.

- Under normal temperature and humidity conditions (room temperature, 50% RH), allow the primer to air dry for 15 to 90 minutes. Because the primer cures on contact with moisture from the air, low humidity requires a longer drying time. The optimal drying time for a particular area should be determined prior to use. A primer that has been left to hard cure will no longer increase adhesion. Drying longer than 6 hours at normal temperature and humidity should generally be avoided.

- Apply silicone sealant.

- Note: Always use a separate container when applying with a brush. To avoid contamination and product deactivation, do not mix used materials into a fresh or unused primer can.

Product title

Vendor

€19,99 EUR | €24,99 EUR

Product title

Vendor

€19,99 EUR | €24,99 EUR

Product title

Vendor

€19,99 EUR | €24,99 EUR

Product title

Vendor