Starter grease

The role of grease in the starter

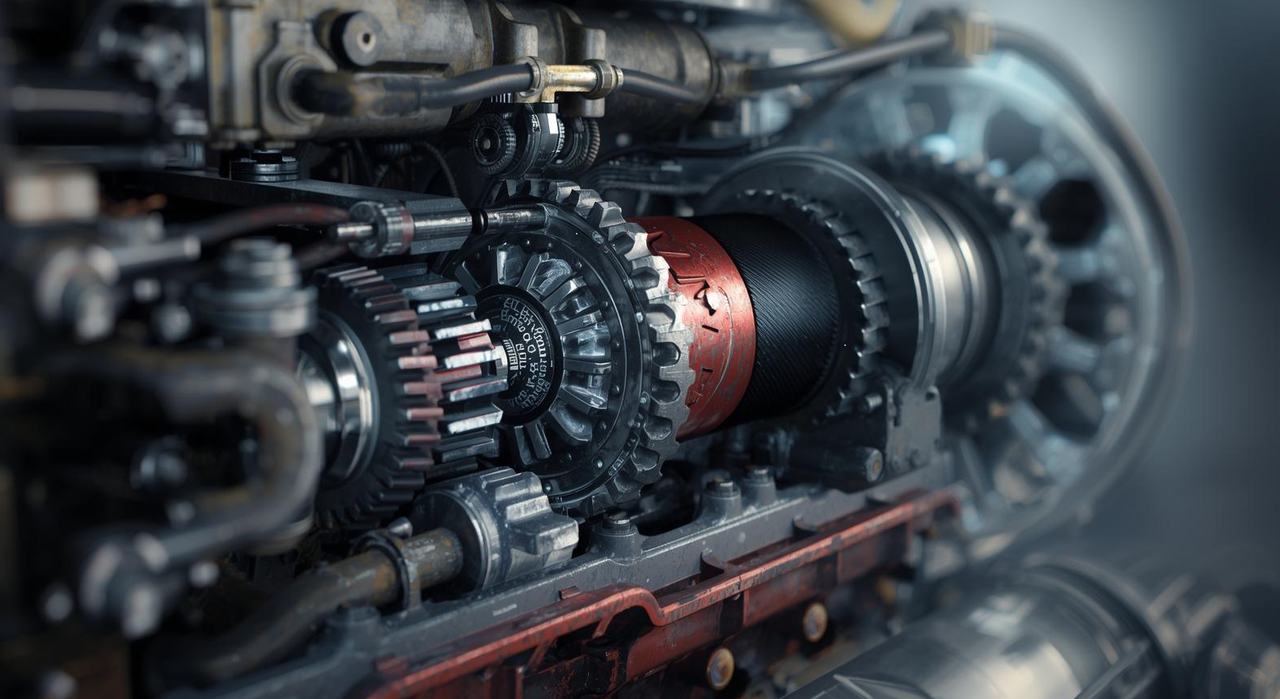

A starter (an electric motor that starts an internal combustion engine) is a device where, in addition to the electrical part, the key mechanical elements are: a gear shaft (Bendix clutch), a planetary gear (in designs with reduction), needle/roller bearings, toothed guides/guides, bushings and sealing rings.

The grease in these areas serves several functions:

- reduces friction between mating surfaces (e.g. gears, shaft and bushings),

- protects against wear and seizure under dynamic loads,

- protects against corrosion and the effects of water, moisture and contamination,

- maintains operating properties over a wide range of temperatures (both low and high),

- works with sealing materials (rubber, elastomers, plastics) without causing their degradation .

Selecting the right grease is therefore crucial for the durability of the starter - too poor quality grease will cause accelerated wear, while the wrong one - e.g. too high consistency - may make installation difficult, cause blockages, and even destroy seals.

Key operating conditions that a starter lubricant must meet

To understand what technical features are required, you first need to look at the operating conditions of the starter:

-

Wide temperature range

o When starting the engine in low temperatures (e.g. very cold conditions), the lubricant must be able to ensure smooth operation at -30 °C, -40 °C or lower (depending on the climate).

o During starter operation, elevated temperature conditions may occur (due to friction, with a hot engine) – up to +100…+180 °C or locally more.

o Therefore, the grease must retain its lubricating properties, not lose consistency, not evaporate excessively and not degrade in this respect. -

Dynamic and shock loads

The Bendix gear engages and disengages with the crankshaft gear – these are dynamic and impact moments.

– The planetary gear, if present, operates under variable torques and peak torques. -

Low rotational speeds or intermittent movements

– In the reduction section and in the Bendix mechanism, the angular speeds are not very high, but good lubrication is required at relatively low rotational speeds.

– The grease must not be too viscous in cold conditions so as not to provide excessive resistance. -

Contact with water, moisture, dirt and corrosion

– The starter motor (especially in the automotive industry) is exposed to water (spray, mud, fog), dust, dirt, salts – the grease must be resistant to water washing and protect against corrosion (e.g. internal surfaces, toothed surfaces).

– It should have anti-corrosion additives and be chemically stable in aggressive conditions. -

Compatibility with sealing materials and elastomers

– Starter motors may contain rubber seals, plastic guides, or sealing rings. The grease should not cause degradation of the rubber (cracking, swelling) or plastics.

– Chemical interactions between the lubricant and housing materials or seals must be minimal. -

Grease durability / low migration / mechanical stability

– The grease should maintain its consistency, not separate, not bleed excessively at high temperatures, and not dry out.

– Low migration is important to prevent the grease from moving to unwanted places or escaping from critical areas. -

Lubrication efficiency with limited volume

– The space for grease in a starter motor is limited – you can't use a large amount. The grease must work effectively in a relatively thin layer.

– It is advisable that the grease has a high load-bearing capacity (ability to carry loads) despite the thin layer. -

Ability to "work from scratch"

– When the engine starts, the lubricant particles must already be present where they are needed – rapid distribution of the lubricant is important. -

Reduced starting friction / ease of installation

– It is recommended that the grease does not cause difficulties in seating mechanical components or resistance during initial movement, which could “jam” the Bendix mechanism. -

Chemical stability, resistance to oxidation and aging

– In the long term (years of operation), the grease should not oxidize, change color, density, or lose anti-corrosion additives.

Key technical parameters of starter grease

Below is a table of technical parameters, standards and values that should be taken into account when choosing a starter grease:

|

Parameter / feature |

Role / Importance |

Typical/Required Values or Ranges |

|

Consistency (NLGI) |

Determines the softness/plasticity of the grease |

Typically NLGI 1 or 2 - class 1 gives better fluidity at low temperatures, class 2 - better retention in the lubricated area |

|

Penetration (worked, 60 strokes) |

A measure of the softness of the grease under measurement conditions |

Typical values 250–320 × 0.1 mm; lower penetration = harder grease, higher = softer |

|

Dropping point |

The upper temperature at which the grease begins to flow |

Minimum 200°C or more; the higher the temperature, the better the resistance to overheating |

|

Operating temperature range |

Determines the limits of grease usefulness |

Typical: from –40 °C to +150…+180 °C (sometimes more) |

|

Base oil viscosity at temp. . 40 °C |

The viscosity of the liquid in the lubricant, which is important for the film layer |

50–300 cSt (depending on design); 100 °C: standard |

|

Weld load / EP load capacity (4-ball test) |

Indicates the maximum load at which the grease protects against seizure. |

Typical requirements: 1500–3000 N (or higher) depending on design |

|

Wear test (4-ball, nominal load) |

Measure of wear of mating surfaces |

Values of 0.3–0.6 mm or less – the smaller the better |

|

Oil bleed / oil separation |

Determines how much oil will separate under test conditions (e.g. 100 °C, 24 h) |

Typically below 5-8%; the lower the percentage, the more stable the lubricant is |

|

Oxidation resistance (thermo-oxidative stability) |

Measures the ability of a grease to maintain its properties over time/temperature. |

Pressure drop in oxidation tests (e.g. 99 °C, 100 h) below 0.1–0.2 bar |

|

Corrosion degree / EMCOR test / Kesternich |

Anti-corrosion protection |

Class 0 / no corrosion / maximum resistance |

|

Water resistance / water washing (washout, water displacement) |

In humid conditions the grease should not be washed off |

Low water wash values required – e.g. small percentage of grease remaining after washing |

|

Adhesion / cohesion (stability under mechanical stress) |

The grease must hold and not "spring off" under load |

Appropriate thickener structure (complex, polymer) / additives |

|

Flash point (closed cup) |

Safety at high temperatures |

Often 200 °C or higher |

|

Color / Identification / Pigments |

Facilitates visual inspection of grease during repairs |

Light/distinctive colors (e.g. light brown, white) |

|

Material compatibility |

Grease resistance to rubbers, elastomers and plastics |

No destruction or swelling of sealing materials |

|

Storage life/long-term stability |

The grease should not degrade in the container |

Typically shelf life 3–5 years in original packaging |

Molykote 7514 as an example of a starter grease

Features of Molykote 7514:

- Operating temperature range: −40 °C to +180 °C

- Dropping point: >200 °C

- Consistency NLGI 1 (soft grease)

- Penetration (25 °C): 290–320 × 0.1 mm

- Base oil viscosity at 40 °C: approx. 49 mm²/s

- Oxidation resistance: pressure drop 0.1 bar (100 h / 99 °C)

- 4-ball wear test (400 N / 1 h): pitting ~0.4 mm

- Oil separation (bleed): 6% (100 °C / 24 h)

- Corrosion test (Kesternich / EMCOR): minimal corrosion class (0–1)

Molykote 7514 is recommended for the lubrication of needle bearings in planetary gears, moving parts of starters, splined shafts and small gears, especially at low temperatures and where water and corrosion resistance are required.

Molykote 7514 is a good example of a compromise: a relatively soft grease (NLGI 1) with a high base oil viscosity, with EP and anti-corrosion additives, capable of operating under conditions of varying temperatures and contact with moisture.

A cheaper substitute for this grease is the Vegatol VPRO Li Complex S 100 EP2 grease with the following parameters:

Vegatol VPRO Li Complex S 100 EP2 :

- Base oil: synthetic PAO with an admixture of esters

- Thickener: lithium complex (Li-complex)

- NLGI Grade: 2 (penetration approx. 265–295 × 10⁻¹ mm)

- Base viscosity: ISO VG ~100 (≈100 mm²/s @40 °C; ≈14–20 mm²/s @100 °C)

- Operating range: typically from −40/−50 °C to +150/+160 °C (continuous)

- Dropping point: ≥ 250–270 °C (often ~280–290 °C for Li-complex)

- Extras package: AW/EP , corrosion inhibitors, antioxidants

- Resistance: low oil separation (bleed), low evaporation, good water and corrosion resistance

- Material compatibility: NBR/FKM seals , typical materials (POM, PA, PBT, ABS, PC)

- Typical applications: high-speed bearings and gears, power tools , alternators, tensioners, small gears in automation

Practical tips for using grease in starter motors

Choosing the right lubricant is one thing – applying it correctly is another. Here are some practical technical tips for applying it:

-

Cleaning the surface before lubrication

– Before applying grease, thoroughly clean all mating surfaces (shaft, bushings, gears) from any remnants of old grease, corrosion and contamination.

– Use solvents compatible with internal materials, then dry. -

Amount of grease/layer

– Do not overdo it: too thick a layer may cause increased resistance torques or even “sticking” during mechanism movements.

– Typically, we apply a thin layer, enough to cover all mating surfaces, but without excessive excess. -

Application method

– Brush, small spatula, grease needle or small gun – depending on design and availability.

– When lubricating gears – good penetration and even distribution.

– In the case of central lubrication systems, the wholesaler can provide lubrication channels – grease with the appropriate consistency (e.g. softer) will spread better. -

Grease "break-in" time

– After assembly, it is recommended to run the starter for a while (without the engine or with lower loads) – this allows the grease to be distributed and the excess to be removed.

– Excess grease can be removed or pumped back in – this will avoid the build-up of grease pressure. -

Regular inspection and lubrication (if design permits)

– In some designs, it is possible to regenerate the grease during operation – this should be done rarely, carefully, in accordance with the manufacturer’s instructions.

– Observe signs of wear – e.g. increased starting torque, noise from the gearbox, increased starter current. -

Avoid mixing with inappropriate lubricants

– If there is already grease inside (e.g. the manufacturer applied it at the factory), the new grease must be chemically compatible – mixing different types of thickeners (e.g. lithium + calcium, lithium + complex, polurea, etc.) can lead to destabilization, separation, loss of viscosity or dissolution.

– It is safest to use the same type of grease recommended by the starter manufacturer. -

Careful sealing

– Lubrication should be carried out while maintaining the integrity of the seals – grease and lubrication piston should not leak onto electrical contacts or insulating elements.

– In case of damaged seals – replace before lubrication. -

Operational tests

– After installation, it is best to test the starter in conditions close to real ones – check the starting torque, internal resistance, operating temperature.

– Whenever possible, check that the grease does not migrate outside the functional areas.

Summary: The most important features of starter grease

From a technical point of view, the ideal starter grease should combine the following features:

- Wide operating temperature range (e.g. from –40 °C to +150…+180 °C), with high dropping point and thermal stability.

- Appropriate consistency – most often NLGI 1 or 2 (or transitional – soft NLGI 1 for better fluidity at low temperatures).

- Good load-bearing capacity / EP properties – ability to protect against seizure under dynamic loads.

- Mechanical stability and low oil migration/separation – the grease must maintain its structure and not separate.

- Corrosion and water resistance – protection of metal surfaces in wet, dirty conditions.

- Compatibility with sealing materials (rubber, elastomers, plastics) – the grease must not cause degradation of the seals or the materials of the starter itself.

- Efficiency with limited volume – a good lubricant must work effectively despite a thin lubrication layer.

- Chemical stability and resistance to aging – long-lasting lubricating properties over many operating cycles.

In addition to our described Molykote 7514 and the much cheaper Vegatol VPRO Li Complex S 100 EP2, similar properties and popular greases include: Shell Gadus S5, Mobilith SHC 100, Repsol Protector Lithium Complex Synt R2/3 V100. Lubriplate SYN EMB , Phillips 66 Multiplex FS 100, Mobilith SHC 100, TotalEnergies Multis Complex SHD 100.

In what conditions, or rather where, are greases of this structure suitable, apart from the starter motor discussed above:

Automotive (engine compartment and accessories)

-

Alternator bearings (2RS) – high speed, increased temperature, vibration.

• Preference: Vegatol S100 EP2 (~VG100 film, NLGI 2) for high mileage and high temperatures; Molykote 7514 when cold starts and minimal resistance are a priority. -

Starter – needle bearings and planetary/intermediate gears , one-way clutch (bendix).

• Preference: Molykote 7514 (lower base viscosity, stronger EP accent, excellent -40 °C); Vegatol S100 EP2 in warmer regimes and for ball bearings. -

Belt tensioners and idlers – high-speed bearings, variable temperatures, salt spray.

• Preference: Vegatol S100 EP2 ; in cold climates – 7514 . -

Electric accessory motors (HVAC blowers, radiator fans, wiper/window lift motors) – high speed, intermittent operation, moisture.

• Both: VG~50 (7514) for ultra-easy starting, VG~100 (S100) for larger C3/C4 clearances. -

Auxiliary pumps (e.g. secondary circuits, secondary air pumps) – high speed and housing temperature.

• Preference: S100 EP2 . -

Locks and hinges in the thermal zone (massive hood/trunk hinges close to heat sources) – water and salt resistance, stability.

• Preference: S100 EP2 (more “body”), possibly 7514 in frosty climates.

Mobility and power tools

-

Bearings for low-power traction motors, pumps and compressors 12–48 V – high speed, continuous operation.

• S100 EP2 for higher temperatures; 7514 for low resistance and starting in frost. -

Planetary gears in cordless tools (screwdrivers, torque wrenches, grinders) – high momentary loads on teeth and needles.

• Molykote 7514 (accent EP + pumpability), in warm – also S100 EP2 . -

Small brushless motors in fans/IT (servers, automation cabinets) – speeds of tens of thousands of rpm, low bleed required.

• 7514 (VG~50) for minimal losses; where tolerances are greater – S100 EP2 .

Light industry and general equipment

-

IE2–IE4 class electric motor bearings (small and medium frames) – long intervals, oxidation stability, limited lubrication.

• S100 EP2 as a “safe standard”; 7514 at very low ambient temperatures. -

High-speed conveyors and rollers (packaging, logistics) – constant speed, dusty, occasional moisture.

• S100 EP2 ; for cold store starts – 7514 . -

Packaging/labelling machines – small, fast, bleed-sensitive bearings.

• 7514 thanks to its light base and good low-T behavior. -

Roof/industrial fans – continuous operation, temperature amplitudes, humidity.

• S100 EP2 (larger film supply). -

Bearings in household appliances exposed to water and temperature (e.g. oven fans, tumble dryers) – mechanical stability and corrosion.

• Both, depending on clearances and thermal regime.

“Borderline” applications where EP and resilience are important

-

Microgears in linear actuators (automation, automotive) – high power density in plastic/metal.

• 7514 (limited lubricity + low viscosity). -

Headlight, sunroof, seat adjustment mechanisms – plastic + metal, low speed, cold/hot pulse.

• 7514 or the “lighter” version of the S100, depending on the design. -

Bearings and gears of medical/laboratory devices (peristaltic, centrifugal pumps) – clean operation, moderate loads, stability requirement.

• S100 EP2 (low bleed, stability).

If you want to choose a grease for the application presented above, check availability at https://sklepsmary.pl/ , call 601 444 149 or abscmt.pl