Sort + Filter

KRYTOX™ - Fluorine greases of the highest quality

Krytox™ are high-performance synthetic perfluoropolyether (PFPE) lubricants that stand up to the toughest challenges, in the most unforgiving environments, across a wide range of industries.

Krytox™ greases are designed for applications where extreme temperatures, non-flammability, oxygen compatibility, longevity and chemical resistance are critical. They perform where other greases fail.

Properties of Krytox oils and greases (PFPE oils and greases)

Krytox fluorinated grease is the best combination of properties

Krytox greases also have excellent low and high temperature performance, allowing lubrication in the temperature range from -70℃ to 399℃.

Best properties in areas where excellent non-flammability, oxygen compatibility and chemical resistance to all chemicals are required, as well as guaranteeing excellent performance and longer service life as a lubricant, sealant and insulator.

Krytox grease and oil composition

Krytox fluorinated lubricants are perfluoropolyether (PFPE), also known as perfluoroalkylether (PFAE) or perfluoropolyalkylether.

These are low molecular weight polymers consisting of hexafluoropropylene epoxide containing fluorine at the molecular terminus. The chemical structure of Krytox oil is as follows. F-(CF-CF2-O)n-CF2CF3ㅡCF3 | where n = 10 to 60. The polymer chain is saturated and consists solely of carbon (C), oxygen (O), and fluorine (F) (without hydrogen (H)). The weight ratio of the components of a typical Krytox® oil is C (21.6 wt.%), O (9.4 wt.%), and F (69.0 wt.%).

Typical properties of Krytox greases

|

Oil type GPL

|

100

|

101

|

102

|

103

|

104

|

105

|

106

|

107

|

|

Standard grease type GPL

|

200

|

201

|

202

|

203

|

204

|

205

|

206

|

207

|

|

High Pressure Grease GPL

|

210

|

211

|

212

|

-

|

214

|

215

|

216

|

217

|

| GPL type anti-corrosion grease |

220

|

221

|

222

|

223

|

224

|

225

|

226

|

227

|

|

Recommended operating temperature range

in °C |

<-70/66

|

<-70/104

|

-63/132

|

-60/154

|

-51/179

|

-36/204

|

-36/260

|

-30/288

|

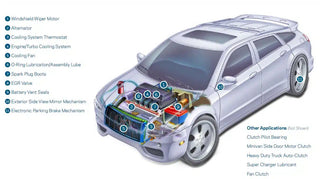

Krytox AUT - Automotive lubricants series: Automotive lubricants

|

Car lubricants |

Grease |

Oil |

|||||

|

CAR 523 |

CAR 2E45 |

CAR 2245 |

CAR 2C45 |

CAR 2045 |

CAR 2E68 |

CAR 1045 |

|

|

Recommended operating temperature range

in °C |

-44/200

|

-44/200

|

-44/200

|

-44/200

|

-44/200

|

-70/200 |

-40/200 |

|

Base oil viscosity at 40℃ |

50 |

100 |

100 |

100 |

100 |

68.3 |

100 |

Krytox for Vacuum Pumps: Series of High Vacuum Lubricants and Oils

| Vacuum Pump Fluid |

Grease

|

Oil

|

||||

|

LVP

|

1506/1506XP

|

1514/1514XP

|

1525/1525XP

|

1618

|

16256

|

|

|

Recommended operating temperature range

in °C |

-15/300

|

-57/149

|

-57/177

|

-51/204

|

-46/232

|

-34/288

|

Krytox XHT Series Very High Temperature Greases - Ultra High Temperature Applications

|

XHT type greases

|

XHT-S

|

XHT-SX

|

XHT-AC

|

XHT-ACX

|

XHT-BD |

XHT-BDX |

XHT-BDZ |

| Recommended operating temperature range in °C |

-20/300

|

-10/300

|

-20/300

|

-10/300

|

-20/300

|

-15/350

|

-5/360 |

Krytox XHT - Very High Temperature Oils - Ultra High Temperature Applications

|

XHT type oils

|

XHT-500(H-1) |

XHT-750 |

XHT-1000 |

| Recommended operating temperature range in °C |

-20/300 |

-15/350 |

-5/360 |

Krytox XP - Greases resistant to rust, wear or extreme pressure

|

Type of oil |

PD 1A0 | XP1A1 | XP1A2 | XP1A3 | XP1A4 | XP1A5 | XP1A6 | XP1A7 |

|

Type of grease |

XP 2A0 | XP2A1 | XP2A2 | XP2A3 | XP2A4 | XP2A5 | XP2A6 | XP2A7 |

|

Recommended operating temperature range |

<-70/66

|

<-70/104

|

-63/132

|

-60/154

|

-51/179

|

-36/182

|

-36/182

|

-36/182

|

Krytox Food Grade: Food Grade Lubricants

|

Food quality

|

FG34

|

FG40

|

|

Grease with anti-corrosion additive |

Oil |

|

| Recommended operating temperature range in °C |

-36/260

|

-35/200

|

Corrugated Cardboard Lubricants - High Temperature Anti-Corrosion Lubricants for Corrugators:

|

Type of grease for corrugator

|

226FG |

227FG |

| Recommended operating temperature range in °C |

-36/260

|

-30/288

|

Krytox EG (electronic lubricants): electricity. Electronic applications

|

Electronic greases

|

EG2000 | EG3000 |

|

Estimated usable temperature range in °C

|

-34/288

|

-29/316 |

Krytox Thread Sealant: Thread Lubricants - for metals and plastics

|

Thread sealant

|

TS4

|

Lubricant for the tire industry - Lubricants for segmented tire molds

| Tire Mold Grease | TM7 |

| Estimated usable temperature range in °C | -20/250 |

| Appearance | White, creamy consistency |

| Standard NLGI penetration grade | #2 |

Krytox Areospace Greases: Aviation greases

|

Type of aviation grease

|

240 AZ

|

240AA

|

240 AB

|

240 AC

|

240 AD

|

|

High pressure grease

|

250 AZ

|

250AA

|

250 AB

|

250 AC

|

250 AD

|

|

Anti-corrosion grease type

|

283 AZ

|

283AA

|

283 AB

|

283 AC

|

283 AD

|

|

Recommended operating temperature range

in °C |

-57/149

|

-51/177

|

-40/232

|

-34/288

|

-29/316

|

Krytox Aerospace Fluorinated Oils: Aviation oils

|

Type of aviation oil

|

143 AZ

|

143AA

|

143 year

|

143 AB

|

143 AC

|

143 AD

|

|

Recommended operating temperature range

in °C |

-57/149

|

-57/177

|

-51/204

|

-46/232

|

-34/288

|

-29/316

|

Military Specs: Mil Spec

|

US

|

. |

NATO

|

|

Specifications

|

Product

|

NSN or FSN

|

| MIL-G-38220 |

Krytox 240 AB

|

. |

| MIL-G-38220 |

Krytox 240 AC

|

9150-00-961-8995

|

| MIL-G-38220 |

(The above two are included in this specification.)

|

|

| TYPE I |

Krytox 240 AZ NLGI CLASS 1

|

9150-01-007-4384

|

| TYPE II |

Krytox 240 AB " " 2

|

9150-01-008-0498

|

| TYPE III |

Krytox 240 AC " " 2

|

9150-00-961-8995

|

| MIS-13429B |

Krytox 240 AC

|

9150-00-082-5539

|

| ANNOUNCEMENT REGARDING NAVAL SHIPS 9230 |

Krytox 240 AC

|

.

|

| SM-C-804199 |

Krytox 240 AZ

|

.

|

| . |

Krytox 240 AB

|

9150-01-008-6197

|

| Grease, multipurpose grease for aircraft and instruments with molybdenum disulfide |

(Molybdenum disulfide certificate in accordance with MIL-M-7866)

|

|

| (Belgian Army) 250 AB with NATO reference number (OTAN) |

.

|

9150-01-008-6197

|

|

MSFC 106B LOX STRIKE

|

KRYTOX 240 AC

|

.

|

Krytox greases for specialist applications

|

GPL-246 |

GPL 206 with added copper, so it will conduct electricity. |

|

GPL-407 |

Silica thickened non-melting thickener for low speed conveyor applications and other such applications where temperatures may cause PTFE to melt. |

|

GPL-577 |

Grease containing special EP and anti-corrosion additives for use under heavy loads where corrosion may be a factor |

|

LVP |

Special high vacuum grease for applications where outgassing must be avoided. It is used in the high vacuum industry and for sealing joints in laboratory applications |

|

PD 2C5 |

XP 2C5 grease contains an oil-soluble additive that effectively prevents corrosion and reduces wear. It also contains an extreme pressure additive. Typical applications include those in potentially corrosive atmospheres where vibration or shock loading may be significant and where the component will spend more time experiencing mixed film or boundary lubrication compared to the desired full film or hydrodynamic lubrication. |

|

XHT EP 298 and EP 299 |

These greases are designed for high temperature applications that require both high load capacity and corrosion protection. Typical applications include conveyor chains that are subjected to wet conditions or frequent temperature cycling that can cause condensation and rust. |